Expert guide: how to take the first steps in RFID tagging for footwear

Looking to dip your toe into RFID for footwear? You've come to the right place. Our team of experts has over 25 years of experience inserting tags into shoes. We're more than happy to share info on why tagging footwear is beneficial, good inlay placement, and the options available through an RFID partner like us.

Why use RFID tagging in footwear?

Supply chain transparency

RFID tagging can help you reach up to 99 percent inventory accuracy without the need for manual counting. Because each product is embedded with its own unique code, you can locate any individual item, no matter where it is in your global supply chain.

Next-generation retail models like omnichannel can only work with this level of transparency, and it also makes revenue-boosting services like click-and-collect or buy-online-pickup-in-store more reliable from a customer perspective.

Improve display compliance

According to our data, RFID tagging also helps to increase display compliance by up to 99 percent, which could lead to a sales uplift of between 2 percent and five percent. After all, if it's not out on the shelves, you can't sell it, so RFID is great at helping you minimize the time taken to replenish. Furthermore, you can tag each shoe separately, so you're more likely to be able to keep a pair together!

Blaze a trail for retail

RFID in shoes can facilitate interactive brand experiences for your customers. For example, adding an NFC (near-field communication) chip to your RFID inlay allows customers to scan shoes with a smartphone to access all sorts of innovative experiences. Embedding a pocket tag in your shoes can also help with authentication, so you can stamp out black market activities by kickstarting your own buy-back and pre-loved initiatives. Smart, eh?

RFID in shoes: how does it work?

RFID tagging for footwear can be tricky. There's a lot of complexity surrounding where the tags can be placed. They need to be accessible and scannable but should also withstand factors like bending and sustained pressure.

That's before we mention the added complexity of tagging a pair of products. Retailers are often left with odd shoes in the stock room or on displays, rendering the pair unsellable. The typical solution is to only tag the box, but this doesn't help shoes out on display. RFID is the way forward!

Read: Everything you need to know about RFID

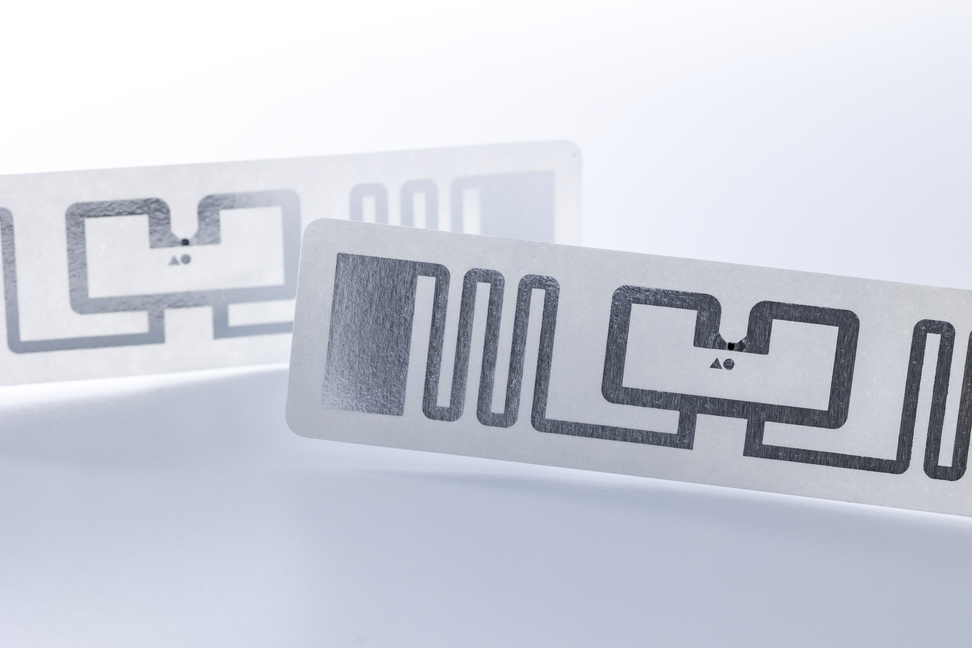

You can choose between self-adhesive RFID stickers which you can apply at source according to the placement guidelines sent by your label partner. This is an easy starter option but comes with the risk of your RFID tags being tampered with by staff or customers.

You can also tag your footwear using 'embedded solutions.' ‘Embedded’ refers to RFID inlays that are hidden within the layers of the shoe itself — usually under the heel of the right shoe. The shoe manufacturing process will determine where your inlay can be embedded, as the goal is to avoid fluids, intense heat, pressure, or metals.

Here are some of our RFID experts' criteria when deciding how to tag different types of footwear with an embedded solution.

Pre-tagging tests

As we mentioned earlier, before a shoe can be tagged, it needs to undergo rigorous testing so your RFID tagging partner can find the right inlay and positioning for you. At Checkpoint, we use a proven testing model that includes the following criteria (among many more!)…

- Avoid putting the inlay on or near steel or metallic shanks.

- Avoid coating the inlay with fluid adhesives or solvents.

- Don’t place the inlay where it might get bent through try-ons or wear.

- Do place the inlays on a ground-smooth surface.

- Avoid placements where the vertical pressure exceeds 15kg for 3 seconds.

‘In-shoe’ RFID testing

Once an RFID inlay shortlist has been selected for your shoe type, your tagging partner will road-test your inlays before signing off on their suitability. For example, here at Checkpoint, we have 'in-shoe' sensitivity checks in our labs to ensure your inlays will be at peak performance once they're hidden within your shoes.

Our main test is a ‘bend’ test to see how long your RFID inlays will survive inside the shoe. Once we’ve collected all the testing data, we’ll make a recommendation, complete with all our findings, so you can make an educated choice.

Best RFID tagging for footwear

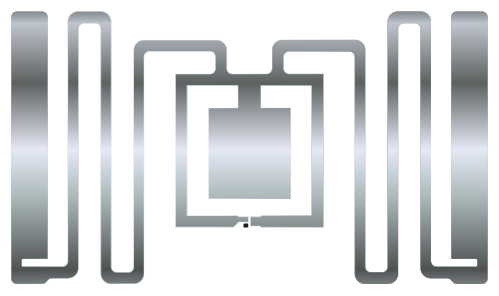

Now that you know why RFID tagging is so beneficial in footwear and how rigorous the testing process is, here are some RFID inlay options typically used in footwear. Each inlay has been designed to fit a different use case and shoe type. Your chosen inlay also needs to pass the tests outlined above. Needless to say, working with an expert is a must!

Vortex

The Vortex inlay is mini but mighty! It has great performance for its size, which is probably why it’s one of our most popular and versatile inlays. The Vortex inlay is usually used in adult footwear sizes.

Triumph

Another one of our versatile inlays, Triumph can be used on general merchandise and footwear. It has an impressively high performance and is smaller than the Vortex, so it can be used in tighter spaces.

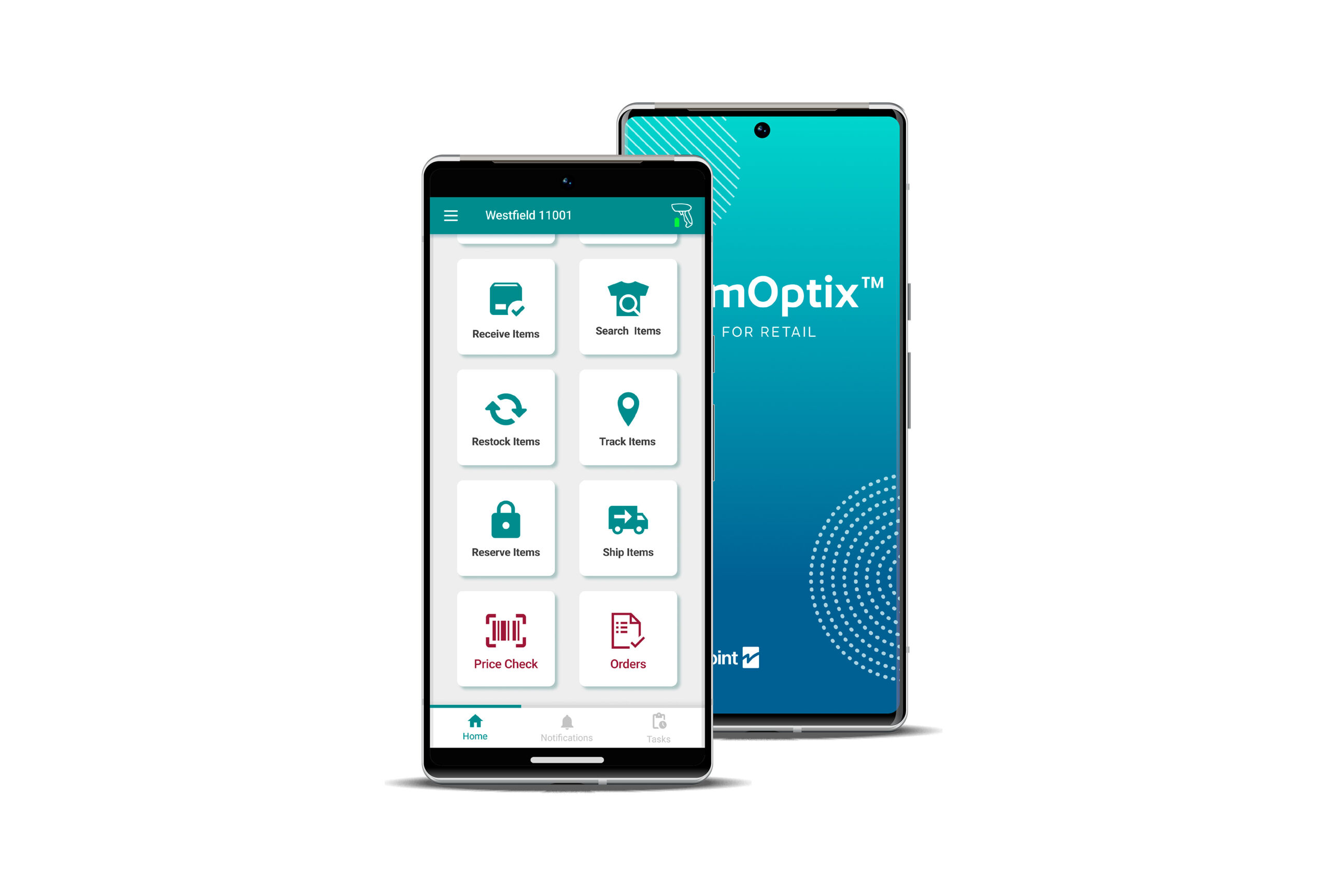

ItemOptix™ for Retail

ItemOptix isn’t an inlay but it is super beneficial for your RFID footwear game. It’s a cloud-based inventory management software that serves up real-time RFID data insights and more besides.

ItemOptix is particularly awesome for footwear because it can differentiate between right and left shoes. It also allows you to have different identifiers for shoes on display versus those in your stockroom, and knows when shoes have moved from one to the other, with the correct hardware. This clever software makes it easier to replenish displays, track shrinkage, and keep tabs on each shoe in the pair. Ideal!