Maximize profits, minimize losses: the benefits of RFID for fashion and apparel

Imagine having 99% stock accuracy* without a manual count or real-time data for effortless display compliance. Every single day. These are just some of the benefits retailers are already seeing with RFID, and with the technology advancing every year, it's just the start of what you could achieve. Our experts share the basics of RFID for fashion and apparel, the three main benefits, and why fast ROI relies on finding the perfect labeling partner.

How is RFID used in the fashion industry?

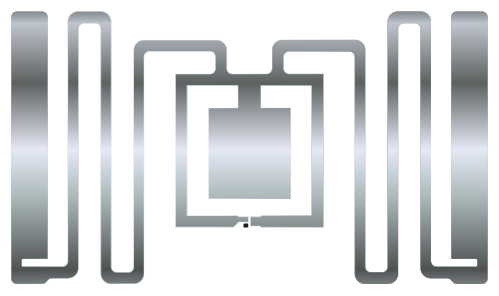

RFID (radio-frequency identification) is quickly becoming the technology of choice for fashion and apparel brands. The technology involves tagging each product with its own uniquely encoded inlay, scannable without a line of sight, and trackable from the moment it's encoded and fitted, right up until the final sale.

The data RFID delivers is critical in the fast-paced fashion industry. It has the potential to give brands the strategic insights needed to identify new growth opportunities, maximize sales, give fab service, and overcome obstacles. Long story short, it’s a game-changer.

One of the best things about RFID technology is its versatility. You can start with something as simple as a roll of encoded RFID hand-applied stickers or go all-in with embedded solutions or even upgrade to dual technology inlays. It’s super adaptable and can be tailored to suit your use case, budget, and goals.

Top 3 RFID benefits for apparel and fashion

Ultimate inventory transparency

* RFID can deliver up to 99% inventory accuracy, opening the door to the seamless omnichannel experience 96% of customers now expect. But you can only achieve it with a minimum of 90% stock accuracy, which is tricky using only manual processes. Once you have full transparency over what you have and where, you can deliver even better service and really put your inventory to work.

Better display compliance and product availability

More stock availability means more sales. Using data generated by RFID, you can reduce the time taken to restock by 90%. Customers get great service, and you get a great profit. Employees won’t need to scan price tags individually either, giving you labor savings of up to 16 times for display compliance.

Improved loss prevention

Loss prevention started with the humble hard tag and has evolved into a near-invisible technology that gives top-notch protection while creating an inviting, interactive environment. New innovations like our customizable SFERO modular loss prevention system or even our combined RF and RFID UNO labels mean you can discreetly tag every garment and boost detection by up to 95%. Better yet, you can use embedded solutions in tandem with hard tagging to keep your high-loss, high-value items safe and sound.

RFID for fashion: finding the right technology partner

A successful RFID rollout needs proper planning and an expert guiding hand — you’ll need the right partner at your side if you’re going to get a swift ROI. Working with a global, vertically integrated RFID labeling partner like Checkpoint means you’ve got an experienced team with you from concept to rollout (and even beyond that).

Decades of working alongside apparel and fashion brands on RFID projects has led us to develop a portfolio of 14 RFID inlays. We’ve also created a fully customizable modular RFID loss prevention system SFERO™ and ItemOptix™ for Retail Inventory Software. Every base is covered!

We don’t gatekeep our knowledge, either. Working with an RFID partner like us means you keep learning on your journey so you can make smarter choices and push the boundaries of innovation alongside us.