3 things you need to know about embedded RFID in woven clothing labels

Meet RFID woven labels — the key to enhanced brand integrity. As a permanent piece of garment branding, everything about wovens should be consistently perfect, from color matching to logos and fonts. And you can make them even more powerful by adding RFID into the mix. Our experts are here to give you the lowdown on what makes these woven clothing labels so intelligent, how they work, and how to decide if they’re right for you.

What are embedded woven labels?

‘Embedded wovens’ refers to the traditional woven garment and branding labels found many garments, but with RFID inlays sewn inside them. They deliver the same aesthetic value to your customers as before, but also the same real-time tracking, cost savings, efficiency, and improved security as you’d expect from any other RFID tagging.

Woven labels, like the ones here at Checkpoint, can be color-matched to your print branding and woven to include arty or photographic imagery. Because the inlay is embedded into the label, RFID wovens are particularly effective at keeping your inlays with their corresponding garments.

How do embedded RFID wovens work?

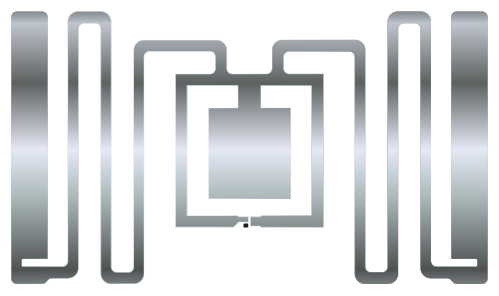

You'd start by working with your RFID labeling team to determine which RFID inlays are best for your woven labels, use case, sustainability goals, and budget. Here at Checkpoint, we have a massive selection of RFID inlays, depending on your goals. For example, some inlays are scannable with a customer smartphone, some have EAS RF capabilities, and some are specially designed for smaller labels.

Read: What is RFID? Everything you need to know

Once you’ve chosen your inlays, your RFID labeling team will use their expertise to get the paper-thin (yet super robust) inlays in between the layers of your woven garment label. Your encoded, embedded wovens are then sent to your manufacturer to be sewn into your garment. This is where it pays to work with a global team like ours — our local teams are on hand to help train and guide your manufacturers on how to use the new labels.

Each scan of your RFID woven label creates new information against that item's unique encoded chip. One scan can reveal info like the time and place of manufacture, purchase history, store or warehouse location, and even the garment composition.

Are embedded RFID woven labels right for you?

Use case

Woven RFID labels are great for frictionless checkout and self-checkout because there’s much less risk of the inlay being accidentally (or deliberately!) removed with the hangtag. In fact, wovens are so crucial to garment branding that it’s not worth damaging the fabric or diminishing the brand integrity by trying to remove them. They’re also a fab option for RFID as EAS — your RFID inlay can be combined with RF technology to work with your existing security gates to help shrink your shrinkage.

Tag size

Bigger inlays can be scanned more accurately from much further away. Embedded wovens are an excellent option if a long-read distance is non-negotiable and you have a nice big label on your garments. We also have much smaller inlays that would fit snugly in a smaller woven, but going big opens you up to more inlay options, bigger read distances, and more functionality.

Easy to see and scan

Embedded wovens aren’t the only RFID clothing tag option we have. For example, pocket tags can be hidden in garment seams and pockets, and care label tags are tucked securely within the garment’s care label. As you can probably tell, embedded pocket tags and care labels are super discreet. Woven garment labels are the best of both worlds because they’re easy to see, access, and scan, but still give you a discreet, secure way to RFID tag your garment.