The ultimate RFID tagging guide: best practices for general merchandise

General merchandise is on the brink of an RFID revolution. It has previously been an area of retail that has remained untouched by intelligent labeling due to the wide range of different products and packaging types and technical challenges, but recent moves by big international retailers has changed all that, opening the floodgates to an RFID revolution.

Our RFID experts walk you through the benefits, requirements, and options available to retailers wanting to RFID tag their general merchandise.

Why tag general merchandise?

There’s a reason why big retailers like Walmart are starting to include RFID tagging in their general list of requirements — it’s been shown to give 99% inventory accuracy. RFID can also deliver a 90% reduction in stock-outs, a 75% reduction in audit costs, and a general sales uplift of up to 4%.

After working with us to implement RFID into their apparel range in 2020, Walmart expanded it into additional departments in 2022 with the goal of becoming fully RFID-enabled. According to them, RFID tagging has increased online order fulfillment, sell-through, and customer satisfaction.

What are the RFID tagging requirements?

Auburn University's ARC program is the go-to resource for tagging specifications. ARC guidelines build on ISO industry standard quality manufacturing certification practices to make sure all RFID tags are up to scratch.

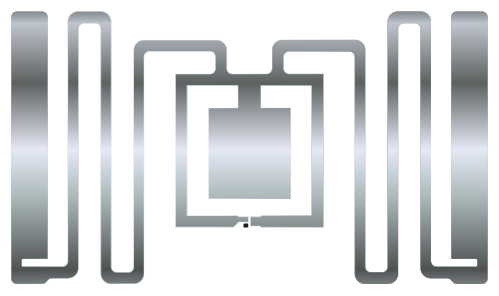

The ARC program has certified use cases for RFID inlays, complete with general merchandise inlay specs, to make sure they fit retailer requirements. If you’ve been asked to tag your products by a retailer, they’ll give you an approved ARC specification to use — you’ll need to know what this entails before you can start tagging.

The good news is that Checkpoint RFID inlays adhere to ARC's specs, so you can choose the best option for your product without worrying about being up to standard.

RFID tags for general merchandise

The team at Checkpoint has spent years extensively testing RFID label solutions and placements through close collaborations with customers. Long story short — we know our stuff!

A word of warning: Metal and RFID don’t play well together. Because of this, we’ll always recommend working with our specialists when tagging metal products or metallic packaging. When in doubt, message us — we’re happy to help.

Integrated packaging

‘Integrated packaging’ is achieved by concealing an RFID inlay in an optimum location within your packaging, usually sandwiched between its layers. It’s especially effective for sleeves, bellybands, trapped blister packaging, or inside box panels. RFID labels, like our are a fab solution for the upcoming Digital Product Passport (DPP) rollout because customers can easily access and scan them through their cell phones

Stickers

Stickers are a good alternative when you can't use integrated RFID packaging. Our RFID labels are available for both hand application and auto-application, depending on your needs and the design of the product you’re labeling.

These are the only products I could confidently call out for this particular label format — all the rest look/sound very similar!

RFID tagging: 5 top tips

Try to avoid putting your RFID stickers in a place that'll put them in direct contact with metal shelving that could interfere with the tech.

Choose your inlay size and shape carefully. It needs to fit neatly into your packaging and be the right size for your required 'read' distance — bigger inlays can be read from further away and smaller inlays have a shorter read distance.

Apply your RFID tag in a tamper-proof location. You don’t want staff or shoppers inadvertently undoing your hard work.

Using RFID adhesive stickers? Check to make sure that you aren’t placing them over key product information.

To avoid conflicting data, only use one RFID inlay per product. If your product comes in multiple cases, you’ll only need one tag on one case. Our team can help you choose the best case to tag.