RFID application guide: how to tag apparel and general merchandise

Do you know how crucial correct RFID placement is? Tagging your products in the wrong place could easily render your labels ineffective or inaccessible. And that’s not all — each product type has an optimum label placement, which determines the kinds of RFID inlay you can choose. And we’re going to teach you all about it.

Our experts have collaborated with brands on RFID rollout projects for decades. Here are their top tips for application, advice on choosing the right label, plus free downloadable resources to show physical placements on unique product types.

RFID tagging: what you need to know first

Tagging a product with RFID technology is more complex than slapping a sticker onto a hang tag. The wrong placement could render the technology useless and stop you from getting all the benefits. And there are plenty of benefits to enjoy — 99% inventory accuracy, a 90% reduction in stockouts, and a 4% sales uplift.

The best place to start is to pick a global labeling partner to collaborate with. Experts like ours have made tailored rollout plans for hundreds of clients and have invented tailored RFID solutions to help them reach goals and targets. They'll help you develop a project plan to suit your timeline and budget, select the best RFID inlays for the job, the best tag format for your use case, and pinpoint the optimum placement.

Choosing the right tag for your products

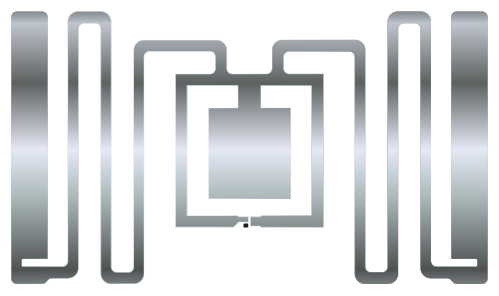

Choosing the right RFID inlay for the job depends on several factors, including placement, product type, read distance, the additional functionality you'd like your RFID to have (if any), and more. Here are the RFID label formats for apparel and general merchandise — the format you choose will dictate the RFID inlay you can use.

General merchandise RFID tag formats

Integrated labels

Integrated RFID labels are the go-to solution for most general merchandise tagging. The RFID inlay is placed discreetly between the layers of packing, making it harder for customers and staff to accidentally remove.

Stickers

Stickers are a secondary solution when integrated RFID tagging isn’t possible. They’re supplied as adhesive labels with variable data information like barcodes.

Hang tags

Hang tags are great for large products that don’t have packaging. You can embed RFID between the layers of the card or apply an RFID sticker according to the guidelines below.

Apparel RFID tag formats

Stickers

Stickers are a great starting point for apparel, as they don’t require supply chain changes. We recommend applying them to hang tags, exterior packaging, or polybags.

Hang tags

Integrated hang tags would replace your regular tags and be applied in your factory. The RFID inlay sits between the label's layers, so there’s no need to alter your branding.

Over-rider

Riders (AKA ‘pocket flashers’) are an integrated solution for trousers and jeans. Your RFID inlay is sandwiched between the layers of the label during production. Easy!

Pocket tags

Your RFID inlay is sewn into a seam behind the care label. Pocket tags are the first step toward innovations like frictionless checkout and are also great for boosting loss prevention.

Content care labels

Your RFID inlay is integrated directly into your existing content care labels by sewing the inlay between the fabric layers.

Brand labels

RFID can also be embedded into your brand labels (depending on size). This can help protect against gray market diversions or counterfeiting, too.

Jacron patches

You can embed an RFID inlay into this traditional denim wear patch and apply it to the garment as usual — no one will be any the wiser!

Where should you avoid placing RFID tags?

On or near liquids

Proximity to liquids can detune your RFID inlay. Storing tagged products in damp locations can also affect how well they function.

Against metal

Metal products, metallic packaging, and direct contact with metal storage shelves can interfere with RFID inlays.

Under heavy loads

RFID inlays may be flat and flexible, but heavy and continued pressure exposure can cause damage.

Exposure to high temperatures

High temperatures can damage your RFID inlay. When in doubt, contact our experts for help finding a solution that works for you.