In today’s business environment, dominated by automation and the need for real-time visibility, Radio Frequency Identification has become an essential tool for industries like retail, logistics, and manufacturing.

However, not all RFID solutions offer the same level of efficiency, scalability, or integration. In this article, we take a close look at the differences between two popular RFID formats: RFID cards and RFID labels, and when to use each.

What is RFID Technology?

RFID enables the identification and tracking of objects using radio waves, without the need for direct line-of-sight. It can operate at various frequencies (LF, HF, UHF), with UHF (Ultra High Frequency) being the most widely used in logistics and retail environments due to its ability to read multiple tags simultaneously over long distances.

What’s the Difference Between RFID Cards and RFID Labels and when use each?

RFID Cards: are rigid and contain a chip and antenna to enable wireless data communication.

They are mainly used to identify individuals or grant access . These typically use NFC and their static and durable format makes them ideal for repetitive, low-volume usage. Known for their rigid structure, physical durability, and ease of use in face-to-face interactions. All typical use cases rely on NFC (high-frequency) technology. They are ideal for enmpoyee identification, building access control, loyalty, and reusable transportation tickets. However, they are less practical in high-volume or automated reading scenarios due to their higher unit cost and need for individual scanning.

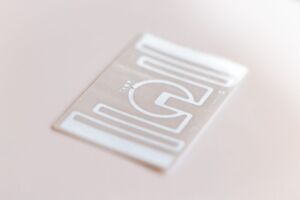

RFID Labels: are adhesive or embedded tags that also contain an RFID chip and antenna but in a flexible form.

These labels can be applied directly to products, packaging, or boxes, making them ideal for environments requiring large-scale traceability, such as retail, distribution centers, and logistics operations. Thin, flexible, and easily integrated into products or packaging. Their low cost and adaptability make them ideal for high-volume applications where speed, automation, and efficiency are critical.

RFID Labels: A Solution Designed for Business Efficiency

Smart labels integrate seamlessly into logistics and commercial processes across industries. They offer several key advantages over RFID cards:

Application flexibility:

RFID labels can adapt to almost any surface: garments, packaging, boxes, or metal products. Their design allows for application at the source, enabling integration from the factory to the point of sale.

Operational scalability:

UHF technology enables the simultaneous reading of hundreds of tags from distances of up to 10 meters, a capability not possible with NFC-based cards, which require individual scanning. This translates into significant improvements in processes such as goods receiving, cycle counting, automated replenishment, and stock auditing.

What’s the Difference Between RFID and NFC?

A common point of confusion is the difference between NFC and RFID. In reality, RFID (Radio-Frequency Identification) is a wireless communication technology used for identifying and tracking objects, and it operates across multiple frequency bands—namely Low Frequency (LF), High Frequency (HF), and Ultra High Frequency (UHF).

NFC (Near Field Communication) is a specific subset of HF RFID, standardized for secure, short-range communication between devices.

The key difference lies between NFC (a type of HF RFID) vs UHF RFID: NFC works at very short range (less than 10 cm) and is mainly used in consumer-facing applications such as mobile payments, scanning product tags with smartphones, or creating personalized in-store experiences. In contrast, UHF RFID offers much longer read ranges (up to 10 meters) and supports bulk reading, making it well-suited for industrial and logistics environments focused on automation and operational efficiency.

RFID Cards or Labels?

Finally, choosing between RFID cards and RFID labels ultimately depends on your specific business needs and operational context.

RFID cards excel in scenarios that require secure, personal identification and controlled access. Their durability and ease of use in face-to-face environments make them ideal for applications like employee IDs, membership programs, and access control systems. However, their cost and the necessity for individual scanning limit their practicality in large-scale or automated processes.

On the other hand, RFID labels are purpose-built for high-volume, automated environments. Their flexibility allows seamless integration into product packaging and assets, enabling real-time tracking and bulk reading capabilities that dramatically improve efficiency in supply chain, retail, and logistics operations. They offer greater scalability at a lower cost, making them the smart choice when traceability, speed, and automation are priorities.

In today’s fast-paced business world, where agility and operational efficiency can make or break competitiveness, leveraging the right RFID technology is crucial. While RFID cards serve specialized personal identification functions well, RFID labels provide the robust, scalable solution necessary to transform and optimize large-scale business workflows.

At Checkpoint Systems, we are committed to smart, sustainable labels tailored to the real workflows of our clients. From the factory to the shelf, and through the logistics center, our RFID solutions help optimize the value chain, reduce costs, and enhance the consumer experience.