As supermarkets seek more efficient ways to manage inventory and enhance customer experience, the debate between barcodes and RFID technology is gaining momentum. In the U.S., global spending on digital transformation is projected to reach $2.8 trillion by 2025 (Statista), driving retailers to adopt smarter solutions. Supermarkets also face challenges such as supply chain disruptions, shrinkage, and food waste, making automation more crucial than ever. While barcodes remain a cost-effective and widely used option, their limitations are becoming more evident in an increasingly demanding retail landscape.

The adoption of emerging technologies like RFID is revolutionizing the way supermarkets manage their inventory and operate in general. In this article, we will explore the key differences between RFID vs barcode and how could shape the future of the retail industry.

What is barcoding and how has it transformed the industry? Limitations to today's requirements

A barcode is a machine-readable pattern of bars and spaces that represents numbers and characters. Found on almost every product in supermarkets and convenience stores, For decades, barcodes have been a standard tool in retail, streamlining checkout and inventory management. However, despite their widespread use, barcodes have certain limitations, such as:

- Requires direct line of sight for scanning: Each product must be precisely aligned with the reader to be correctly identified.

- Does not allow simultaneous reading of multiple products: Products must be scanned one by one, slowing down payment and inventory processes.

- Limited data storage capacity: A traditional barcode only contains basic information, such as the product's Stock Keeping Unit (SKU) number.

What is RFID and how does this technology work? Is RFID better than barcodes?

First of all, what is RFID? This is a technology that uses radio waves to transmit data stored in electronic tags. The main difference from barcodes is that RFID does not require direct visual contact for reading, allowing for much more agile and efficient product management. RFID system is based on three main components: tags, small electronic devices that store information; hardware, which emit signals to detect and read tags; and software, which receives and processes the information. This technology presents many benefits for sectors such as grocery. Among them, the following stand out:

- Reading without the need for line of sight: Allows product registration without the need to pass them through the barcode reader, which streamlines product management.

- Mass scanning of products in seconds: Helps verify inventory quickly and accurately.

- Real-time inventory management: Helps reduce losses due to unlocated or expired products.

- Automation of contactless payment: Thanks to self-checkout systems, it improves the customer experience at the cash register.

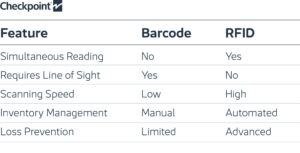

Barcodes versus RFID: a face-to-face comparison in supermarkets

The decision to use barcodes or RFID technology in supermarket depends on several factors, such as business size, product turnover, and operational efficiency goals.

- Scanning Method

- Barcodes: Require individual scanning with a clear line of sight, making checkout and inventory management more time-consuming.

- RFID: Allows multiple items to be scanned simultaneously without direct visual contact, speeding up stock counts and checkout processes.

- Efficiency in High-Volume Sales

- Barcodes: Work well in standard checkout lanes but may slow down operations in high-traffic environments due to the need for manual scanning.

- RFID: Instantly detects all tagged products passing through a reader, reducing checkout times and improving replenishment speed.

- Loss Prevention

- Barcodes: Only register product movements when scanned, offering minimal protection against theft.

- RFID: Provides real-time tracking, alerting security if an item is removed from the store without being purchased.

- Inventory Management

- Barcodes: Require manual stocktaking, where each item must be scanned individually, increasing labor costs and the risk of human error.

- RFID: Enables automated, real-time stock tracking, reducing the likelihood of out-of-stock situations and optimizing restocking.

- Implementation Costs

- Barcodes: Low-cost solution with minimal infrastructure investment.

- RFID: Higher initial costs but offers long-term benefits in efficiency, loss prevention, and customer experience.

- Durability and Readability

- Barcodes: Depend on being readable at all times and can become damaged over time, leading to scanning issues.

- RFID: More robust and durable, requiring significant damage to become non-functional, ensuring better long-term reliability.