When hiring an RFID provider, it is essential that they hold ARC certification, which guarantees the compatibility and performance of RFID tags to ensure their effectiveness. Issued by the Auburn University RFID Lab in the United States, ARC certification verifies the necessary quality to consistently and cost-effectively deliver user benefits. But what exactly is this certification, and why is it crucial for your RFID tags? Let’s know more about it.

What is ARC Certification?

ARC Certification (Auburn RFID Lab Certification) is a globally recognized standard that validates the quality, performance, and consistency of RFID tags in specific environments. This certification process ensures that a tag meets the technical and functional requirements for applications such as logistics, retail, and healthcare and demonstrates the supplier's ability to manufacture inlays and labels with consistent performance and high yields. Auburn Lab tests RFID tags in real-world scenarios and under various environmental and operational conditions to ensure compatibility with RFID readers and the systems businesses use. By certifying consistent manufacturing quality, ARC ensures that the production process remains controlled and reliable, offering businesses confidence in the tags' performance over time.

Recently, Checkpoint Systems positioned itself as a pioneer by integrating the latest generation of RAIN RFID ICs into its ARC-certified inlays. These chips stand out for their high sensitivity, energy efficiency, and compact size. This innovation makes them ideal for applications in products like footwear and clothing, delivering superior performance and adapting to the diverse needs of retail and logistics. The ARC certification, achieved across multiple specifications at the Auburn RFID Lab, ensures reliability and compatibility.

Further underscoring its commitment to excellence, Checkpoint successfully achieved 2025 ARC Quality Certification, meeting the ARC quality requirements for the design and manufacturing of RFID inlays. With one of the industry’s most extensive ranges of RFID tags, Checkpoint provides solutions tailored to diverse needs and use cases. This achievement is bolstered by a robust Quality Management System (QMS) in its manufacturing facility, ensuring RFID tag performance is consistently upheld across time and volume.

Auburn's ARC program, regarded as the universal standard for defining passive UHF RFID inlay requirements, has been instrumental in advancing the RFID ecosystem. Trusted by leading retailers like Walmart and Dick’s Sporting Goods, the program supports end-users across industries.

How Does ARC Work?

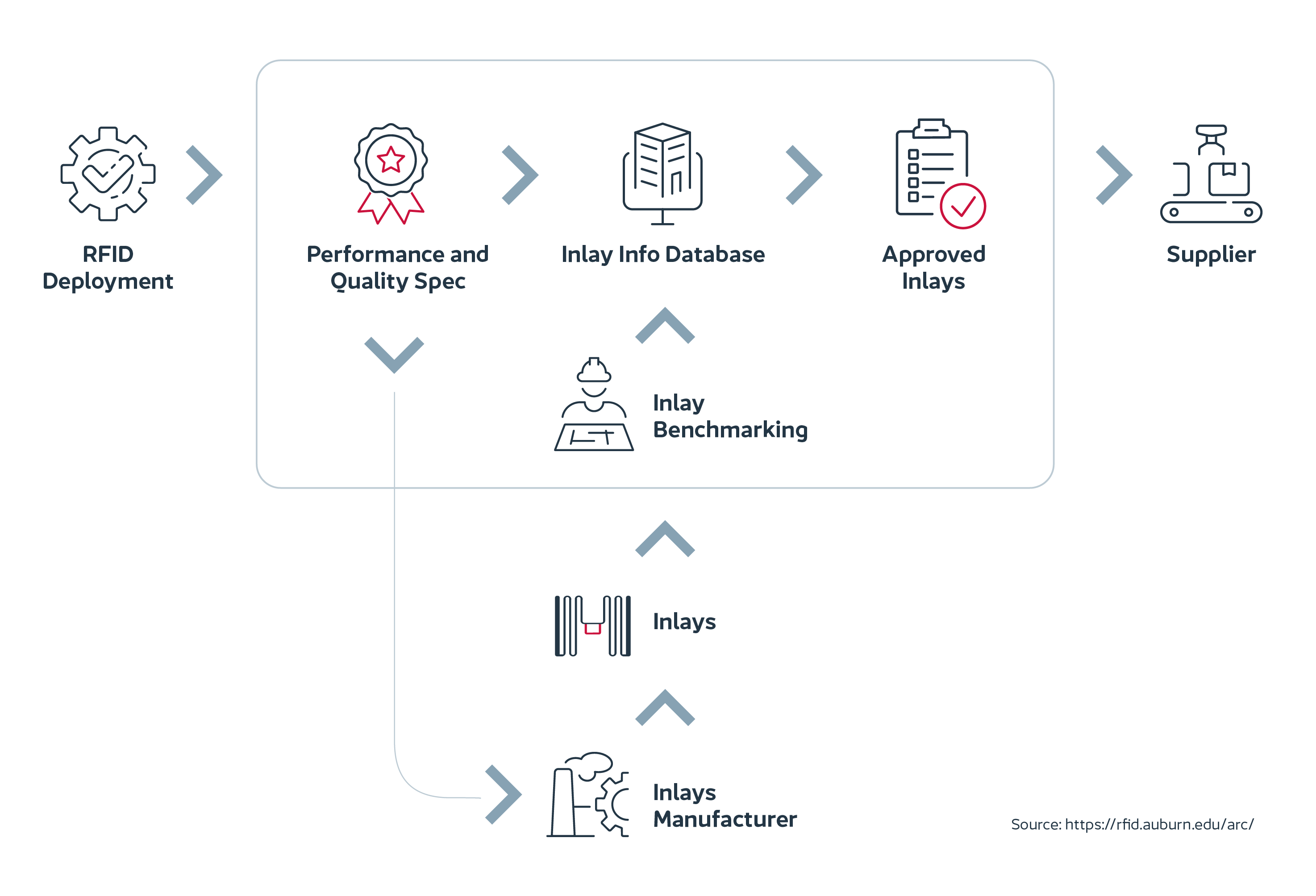

ARC works closely with end users in sectors such as retail or manufacturing to identify the performance and quality requirements necessary for RFID use cases and implementations. These specifications set the standards that an RFID tag must meet to ensure reliable functionality in these applications.

Auburn Lab manages a comprehensive database containing detailed information about the performance and quality of RFID tags available on the market. This database enables the rapid generation of lists of tags that meet end-user specifications, simplifying the selection process for each implementation.

Before launching new products to market, manufacturers of RFID tags send their products to ARC for evaluation. The lab measures the performance of each tag, compares it against existing specifications, and, if it meets the requirements, includes it in the list of approved tags for that specification.

ARC testing methodology is transparent and, while the procedures are clearly defined, the process undergoes regular evaluations and continuous improvements to adapt to the evolving needs of the market.

Why is it key to work with an ARC-Certified provider?

- Ensures Optimal Performance: ARC certification guarantees that RFID tags meet the necessary standards for specific applications, reducing the risk of system failures such as inaccurate readings or undetectable tags.

- Enhances Interoperability: Companies often use RFID devices from various manufacturers. ARC certification ensures that tags are compatible with these systems, preventing integration issues.

- Builds Customer Confidence: For companies implementing RFID, ARC certification provides reassurance. This recognition guarantees that tags have been tested in rigorous scenarios and meet the highest standards.

- Reduces Long-Term Costs: Investing in ARC-certified RFID tags avoids additional expenses from failures, replacements, or inefficient systems.

ARC certification not only validates the performance and quality of RFID tags but also ensures that these tags will function seamlessly in the specific applications and environments for which they were designed. Choosing tags with this certification is a strategic investment that guarantees efficiency, reliability, and long-term savings. If you have plans to implement RFID technology, opting for ARC-certified tags is an essential step to ensuring the success of your operations.