Why RFID stickers are the easiest place to start your RFID journey

Are you considering RFID rollout for your retail business? RFID stickers are an easy, accessible way to start the process. Here’s what RFID tag stickers are, how the technology works, and why retailers rely on them.

What is an RFID sticker?

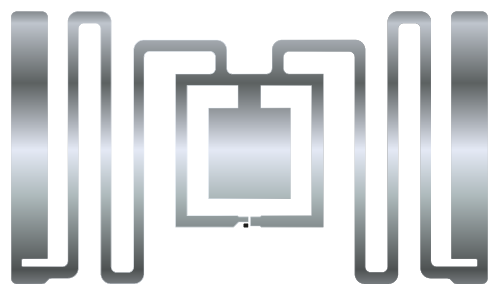

An RFID sticker is a self-adhesive label with an RFID inlay on the back. It uses radio-frequency identification (RFID) to record, store, and transmit unique product information wirelessly. Your RFID sticker consists of a chip to store unique product information and an antenna which sends the info to a device when scanned. The chip and the antenna are both neatly mounted on an inlay, like so…

How do RFID stickers work?

RFID stickers are printed and encoded by a label supplier and sent to you as a sheet/roll, ready to stick to packaging and hang tags. Stickers can even be printed with variable data or pricing information, depending on your needs.

To use RFID stickers, you’ll need three things:

- Encoded RFID stickers from a supplier like us

- An RFID reader (usually a hand-held scanner)

- RFID software to store and record the data from your stickers

You start by scanning your sticker with an RFID reader, which sends a blast of radio waves out to the antenna in your RFID inlay. The radio waves create an electronic current in the RFID chip, giving it enough power to fire its unique info back to the reader.

Part of what makes RFID stickers a good starting point is that they don’t need to be applied at source, so you can jump right in without adding too many logistical steps to the process. RFID stickers are ready to apply right out of the box and stick neatly to most products, including hang tags and shoe boxes.

RFID software can also be relatively simple to implement. For example, our cloud-based ItemOptix™ for Retail is an ‘open’ form of software, so it integrates easily with almost any system.

What are RFID stickers used for?

An accessible route into RFID technology

RFID stickers are simple to order and implement. You’ll receive a sheet/roll of pre-encoded stickers ready to stick to your stock. Give it a scan, and you’re ready to roll.

Compared to other forms of RFID, this is a relatively simple process. For context, here at Checkpoint, we’ve got an entire portfolio of different RFID options over a variety of formats, like hang tags and sew-in solutions. Some even blend RFID with other chips, like NFC and RF to double the capabilities of the inlay. There’s a whole world of RFID to explore, but the first, most achievable step is a sticker.

Frictionless stock count

RFID stickers can save you a ton of time and money where labor is concerned. RFID gives a faster, more accurate inventory count — 43 times quicker and up to 99% accuracy, according to our figures. The tech allows your staff to spend more time giving great service on the shop floor rather than counting stock in the back room.

Quicker replenishment (and better customer service)

Out-of-stocks and sparse displays are revenue killers. After all — shoppers can’t buy what they can’t see! RFID stickers are an easy way to gain better inventory visibility, fast. Data gathered from our clients has shown that RFID can reduce out-of-stocks by up to 90% and increase stock availability by 13.46%. The more you replenish, the quicker your stock will move.

Makes click-and-collect or BOPIS easier to implement

Are you quick enough to meet modern customer expectations? It’s common for shoppers to buy online and expect pick-up within an hour of ordering. You’ll need to be quick if you want to give excellent service…and that kind of speed is really only possible with technology like RFID.

Retailers who tag and scan inventory with RFID stickers are much more likely to have better stock accuracy than those who rely on manual stock counts. Not only are you less likely to come up empty on the item the customer has ordered, but you can also find it faster.

Opening the door to dozens of possibilities

RFID stickers are the tip of the iceberg when it comes to the possibilities available to you. RFID technology has advanced to give you dozens of different functionality options, depending on what you’d like to improve in your business.

Using our own RFID portfolio as an example, products tagged with RFID Compass inlays can be tracked to better understand stock movement around the store. UNO labels work with your existing loss prevention hardware to turn your garment labels into EAS tags. DUÉ Mini labels combine UHF-RFID and NFC technologies to make your labels interactive at the touch of a smartphone.