RFID labels - How to handle and store

Best practices

In order to get the best performance possible from your RFID inlays and labels, we have put together the following guidelines and advice.

Failure to do so will result in permanent damage.

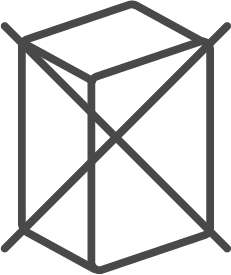

Do not store under a heavy load

Keep in a dry place

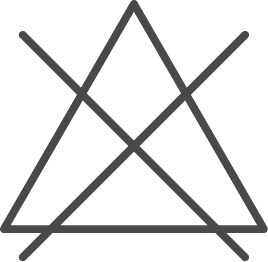

Do not expose to heat

General recommendations

1. Tags are electronic devices with sensitive RF properties and can break if not handled with care.

2. Make sure that the application of tags follows the correct procedures to ensure highest performance and quality.

3. Metallic or conductive materials are not suitable for RFID labels as they may weaken RF performance. (Except for specific RFID metal labels)

4. Handling of RFID products shall be performed by trained personnel only. In case of doubt, please consult Checkpoint Systems.

No static electricity

No

puncturing

No

tearing

No

folding

No

cutting

No

buttons

No

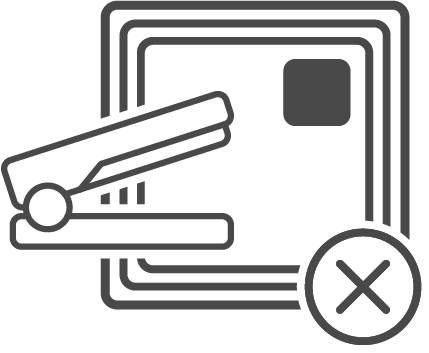

stapling

No

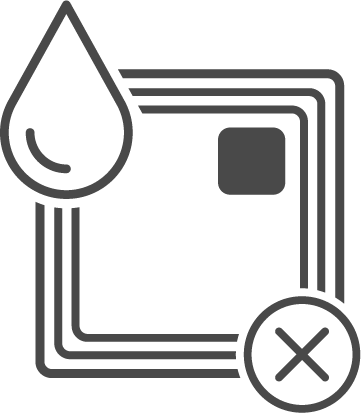

liquids

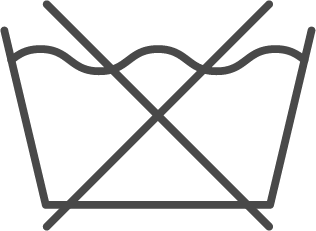

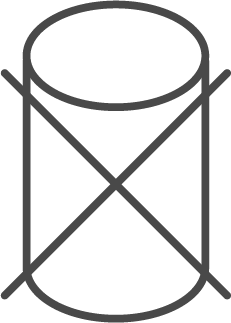

No washing or stone washing

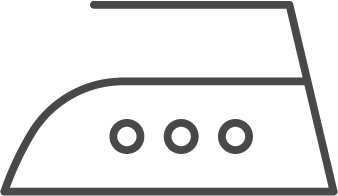

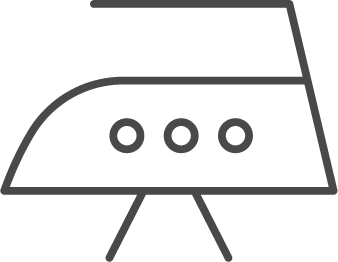

Direct ironing - Max 2 seconds

Direct steaming - Max 2 seconds

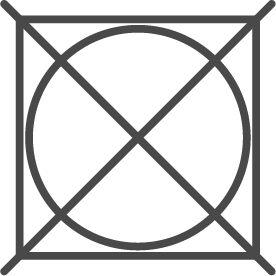

No spinning or tumble drying

No

dry cleaning

No

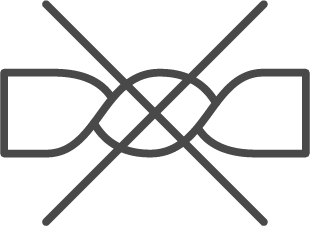

wringing

No

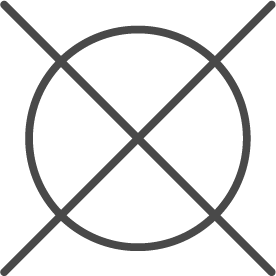

bleaching

No application on metal*

No metal foil application

No

glue**

*Unless a specific RFID on-metal label, please consult Checkpoint Systems if unsure

**Other than the glue already applied to your chosen RFID form factor (ie, sticker)