In an increasingly demanding logistics environment - where speed, accuracy, and traceability are critical factors - RFID technology has become a key solution for transforming the supply chain. However, its successful implementation heavily depends on the technical knowledge, integration capabilities, and hands-on experience of the involved players.

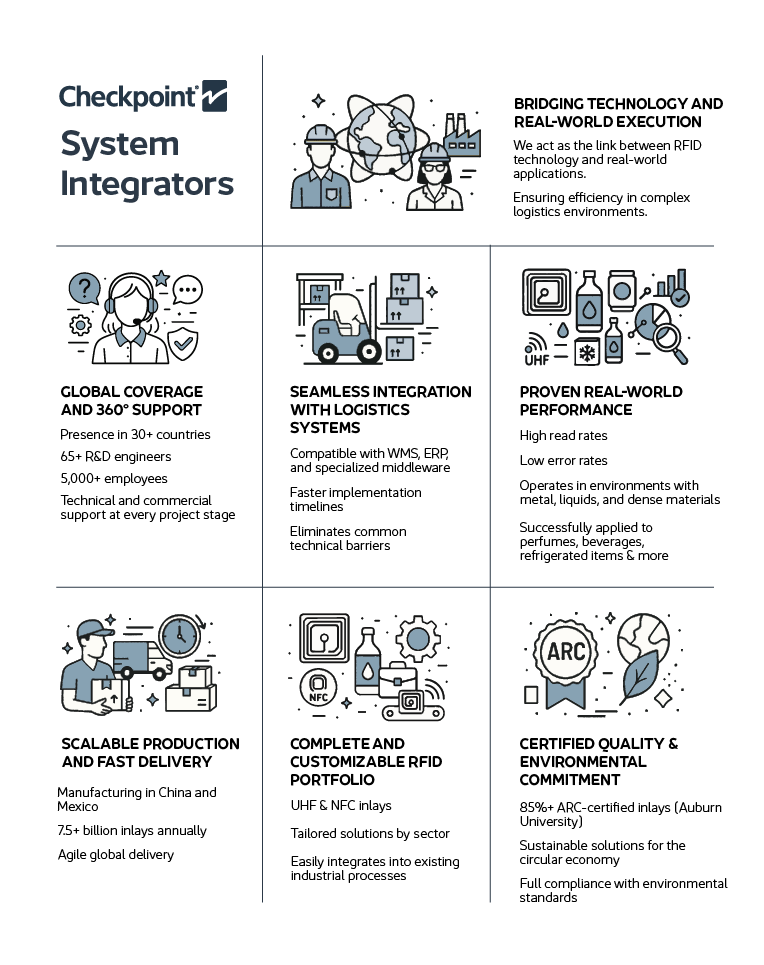

This is where RFID system integrators play a fundamental role: they act as the bridge between technology and real-world application, ensuring that solutions perform efficiently in complex, large-scale scenarios. For these integrators, having a reliable, innovative partner ready to face the challenges of the logistics sector is essential.

Checkpoint Systems meets that need with a robust offering: reliable, scalable RFID inlays ready to integrate into any logistics environment. Below, we explore why it is the ideal strategic partner for integrators seeking to drive high-impact, results-oriented projects.

Why choose Checkpoint if you are a system integrator?

Checkpoint Systems is the ideal partner to implement smarter, scalable, and reliable solutions in the logistics sector. With global reach, a comprehensive RFID solutions portfolio, and deep technical expertise, we enable projects that demand precision, speed, and constant adaptability.

With a strong history in RFID tagging and traceability, and a presence in over 30 countries, Checkpoint partners with integrators throughout the RFID system lifecycle - from technical definition to deployment, support, and scalability. This combination of global reach and technical leadership makes us a trusted partner for long-term success.

Seamless RFID Systems Integration with Logistics Software & Hardware

One of Checkpoint’s key differentiators is its ability to integrate seamlessly with complex logistics environments. Its RFID solutions are pre-tested to ensure compatibility with leading logistics hardware. This smooth integration shortens deployment timelines and eliminates common technical barriers in RFID projects.

Enterprise-Grade RFID Systems Performance in Real-World Supply Chains

Checkpoint’s RFID solutions have proven consistent performance in real operating conditions, including highly demanding sectors like food, cosmetics, apparel, and logistics. The inlays are designed to operate in environments with high product density, complex materials, or interference from metals and liquids.

This allows integrators to offer solutions with high read rates, minimal failure rates, and improved operational efficiency. Applications range from pallet, case, to item-level tagging for real-time inventory management - reducing errors, losses, and response times in the supply chain. These solutions have been successfully applied to items such as perfumes, beverages, and refrigerated goods, among others.

Scalable RFID Systems Production with Global Reach

Checkpoint also has a scalable production infrastructure that allows us to quickly respond to project demands—regardless of volume or location. With manufacturing centers in China and Mexico and the capacity to produce over 7.5 billion inlays per year, the company ensures agile delivery and consistent quality.

In addition to its industrial capabilities, Checkpoint provides technical and commercial support in more than 30 countries, with over 65 R&D engineers and more than 5,000 employees. This global network allows integrators to execute multinational projects with confidence, maintaining competitive delivery times and localised support when needed.

Complete RFID Systems Portfolio with Custom Integration Options

Checkpoint offers a comprehensive RFID portfolio, including UHF and NFC inlays in various sizes, materials, adhesives, and formats. From pallet labels to omnidirectional tags, each inlay is designed with sector-specific challenges in mind.

For integrators, this means access to an expanding portfolio of ready-to-use solutions designed for emerging applications and high-potential markets. We focus on developing innovative inlays that address previously unserved or technically complex use cases, enabling the successful execution of high-complexity projects with a differentiated value proposition.

We can also collaborate with local partners to deliver products in the exact format each operation requires - easing integration into existing industrial or logistics processes.

Certified Quality and Sustainability You Can Rely On

Quality and sustainability are key pillars of Checkpoint’s value proposition. Over 85% of its inlays are certified under Auburn University’s ARC program - a global benchmark in RFID quality standards. This certification has been crucial for becoming an approved supplier for chains like Walmart.

Our inlays are designed to adapt to and enable sustainable solutions. We support reusable applications and the circular economy through innovations such as IML and H2O RFID labels. RFID tags play a key role in driving sustainability by enabling systems that reduce waste and improve efficiency. For integrators, this means the ability to deliver solutions that meet both technical and evolving environmental demands.

Conclusion: Powering Smarter RFID Deployments with Confidence

Choosing Checkpoint Systems as a strategic partner means gaining access to a unique combination of experience, innovation, flexibility, and global capability. Its customer-focused approach and cutting-edge technology offering empower system integrators to deploy RFID solutions that are faster, safer, and more adaptable.

Whether the goal is to improve supply chain visibility, reduce operating costs, or ensure complete product traceability, Checkpoint provides the tools needed for a successful implementation. In a constantly evolving market, having a partner like Checkpoint is a smart choice to meet today’s challenges and seize tomorrow’s opportunities.