RFID technology has become an essential tool for improving traceability, inventory management, and operational efficiency across a wide range of industries. However, the terminology can be confusing for those unfamiliar with it. What are RFID inlays, and how do they differ from RFID tags or labels?

In this article, we’ll explore the differences between these three terms and their uses to implement this technology for operational efficiency.

What is an RFID Inlay?

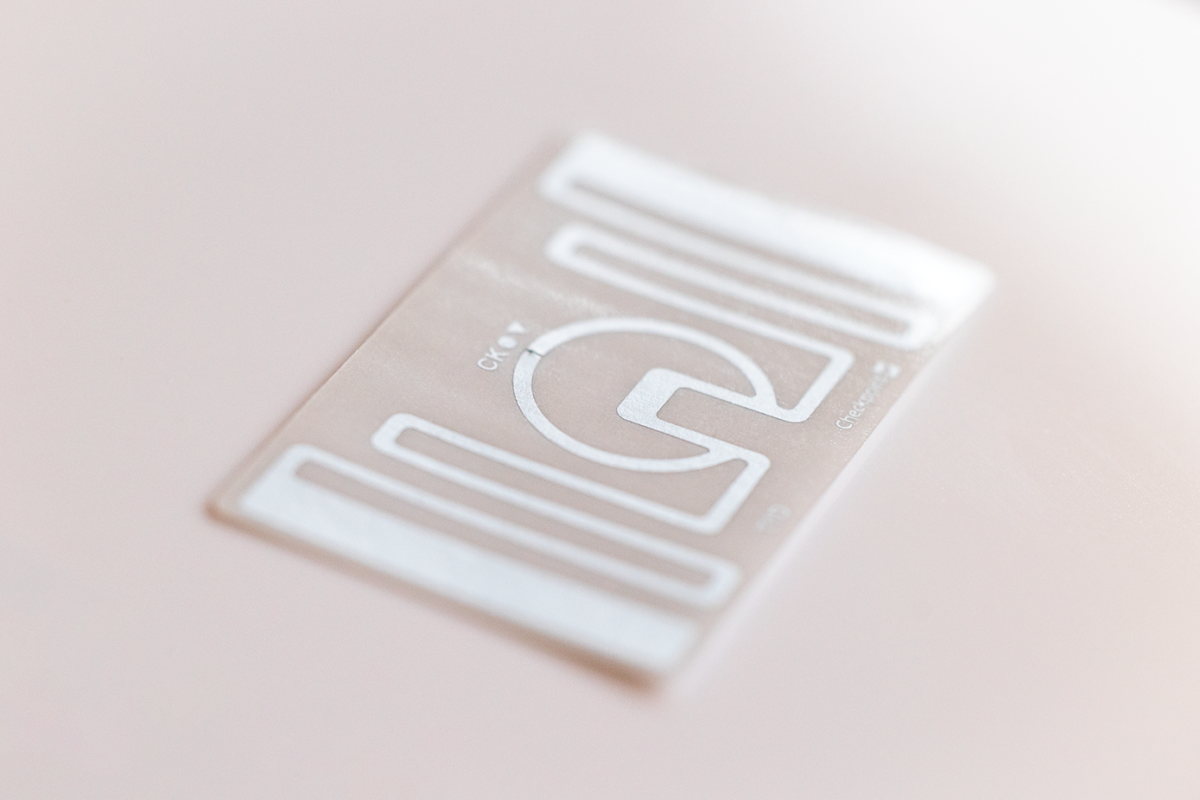

An RFID inlay is the basic component that enables the function of RFID tags or labels. It consists of the RFID chip and the antenna that transmits data. Inlays lack their own casing, making them fragile and prone to damage unless properly protected.

The inlay is the heart of any RFID system. RFID labels incorporate this component, making it a lightweight and cost-effective option.

Understanding RFID Labels

An RFID label, called RFID Tag as well, is a type of label that uses radio frequency identification (RFID) technology to store and transmit data wirelessly through radio waves.

When compared with traditional labels, which are limited to delivering information that is written on them, RFID labels have the capacity to store and send dynamic data that is updated in real time. Because of this, they are perfect for use in asset tracking, inventory management, and other applications where real-time data is crucial.

RFID labels can be applied to products and merchandise. In addition to RFID functionality, these labels can feature printed information such as barcodes, product names, or logos, offering both visual and trackable data. So, what are RFID labels? They are an efficient solution for combining traditional labeling with modern RFID tracking.

There are two types of RFID Labels/Tags:

- Active: These tags have an internal battery that continuously emits signals, making them useful for tracking items over long distances.

- Passive: These tags have no internal power source and only activate when within range of an RFID reader. When an RFID label is placed near a reader device, the radio waves from the reader to activate the chip in the label, allowing it to send information back to the reader.

Key Differences Between RFID Labels, and Inlays

| RFID Inlay | RFID Label | |

|---|---|---|

| Composition | Chip RFID + aluminum antenna + PET Carrier | RFID Inlay inside a label |

| Resistance | Low, no inherent protection | Moderate |

| Use Case | Used within tags or labels | Retail products, inventory management, stock control, antitheft |

RFID labels and inlays are key parts of RFID technology. RFID labels combine visual information with RFID tracking capability. They contain an RFID inlay, which is the essential component consisting of a chip and antenna that enables RFID functionality. Understanding the differences between RFID tags or labels and inlays might help make informed decisions that maximize efficiency and minimize costs.